Go Back

Workflow Rescue Program

Problem:

The client, a growing Small and Medium-sized Enterprise (SME) in the logistics and supply chain sector, was struggling with escalating inefficiencies rooted in outdated operational processes.

Although the company had a strong client base and reliable service reputation, its internal workflows were largely manual and paper-based, relying heavily on spreadsheets, email chains, and handwritten delivery logs.

As operations expanded, these systems became unmanageable. Departments such as dispatch, inventory control, billing, and customer service all maintained independent data silos, leading to duplication of effort, inconsistent records, and delayed reporting. Approvals for shipment releases, payment confirmations, and route scheduling required multiple email exchanges and manual reconciliations.

The cumulative effect was frequent process delays, rising operational costs, and frustrated staff. Key business pain points included:

Shipment tracking delays due to manual status updates.

Errors in invoicing and reconciliation caused by inconsistent data entry.

Bottlenecks in approvals, especially during peak dispatch periods.

Limited visibility across departments, preventing data-driven decision-making.

Over time, these inefficiencies translated into revenue losses and strained customer relationships, as clients experienced slower response times and inconsistent delivery updates.

The management recognized the urgent need to modernize operations by replacing manual workflows with digitized, streamlined, and scalable systems — without the financial burden of enterprise-level automation platforms.

Our Approach:

We approached the engagement as a comprehensive workflow transformation, focused on simplification, digitization, and human adoption.

1. Operational Audit and Process Mapping: We began with a detailed process audit across all major departments — logistics operations, customer service, finance, and dispatch coordination. Using process mapping and time-motion analysis, we documented every task from order intake to delivery confirmation. This audit revealed that staff spent over 40% of their daily hours on repetitive administrative activities such as data entry, file searching, and status updates — tasks that could easily be automated. It also uncovered process redundancies, such as triple-checking approvals and unnecessary paper-based signatures, which contributed to bottlenecks.

2. Workflow Redesign and Simplification: DWe collaborated with department heads to redesign each process for speed, clarity, and accountability. Tasks were re-sequenced to eliminate dependencies and parallelize workflows wherever possible. We introduced standardized templates for data capture and developed unified process flowcharts to ensure cross-departmental alignment.

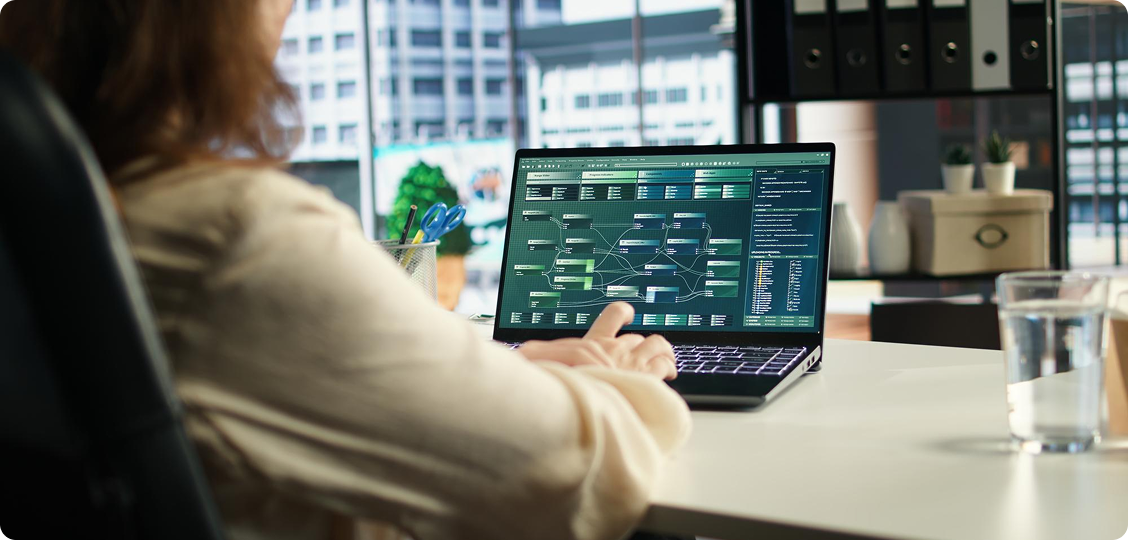

3. Introduction of Low-Code Automation Tools: Recognizing the client’s limited technology budget, we implemented affordable low-code automation tools such as Airtable, Zapier, and Google Workspace integrations to digitize repetitive tasks.

Examples include:

- Automated data entry and routing forms that fed directly into centralized dashboards.

- Instant approval workflows with digital notifications for managers.

- Smart trackers for dispatch and payment reconciliation that updated automatically as tasks were completed.

These automations reduced reliance on manual spreadsheets and established a single source of truth for operational data.

4. Development of Adoption Playbooks: To ensure smooth transition and prevent resistance, we created step-by-step operational playbooks for every redesigned process. These guides detailed how to use the new tools, escalation procedures, and key performance indicators. The playbooks were designed as simple visual handbooks — easy for non-technical staff to follow.

5. Capacity Building and Change Management: We held department-specific training workshops to build staff competence and confidence with the new systems. Special sessions were held for team leads to equip them as “change champions” responsible for monitoring compliance, offering peer support, and ensuring sustained adoption.

A 30-day feedback loop was established to capture early-stage challenges, fine-tune workflows, and improve usability.

Timeline:

10 Weeks Total

- Weeks 1–2: Process Audit and Mapping

- Weeks 3–5: Workflow Redesign

- Weeks 6–8: Tool Implementation and Testing

- Weeks 9–10: Training, Rollout, and Handover

- A post-deployment monitoring phase continued for an additional 30 days to ensure system stability and employee adaptation.

Results:

The transformation yielded both measurable operational gains and qualitative cultural improvements within the first quarter:

- 50% Reduction in Process Delays: Automating approvals, status updates, and data entry dramatically accelerated internal response times.

- 23% Increase in Productivity: Staff could redirect their focus from clerical tasks to higher-value activities such as client relationship management, route optimization, and service improvement.

- Error Reduction: Invoicing and reporting accuracy improved by 35%, minimizing revenue leakages and client disputes.

- Enhanced Data Visibility: Managers gained real-time access to key operational metrics via dashboards, enabling faster and more informed decision-making.

- Employee Satisfaction: Post-project surveys indicated a 70% improvement in job satisfaction, attributed to reduced administrative burden and clearer task ownership.

Financially, the improvements resulted in significant cost savings on overtime and administrative rework, while improved turnaround times strengthened customer trust and repeat business.

Culturally, the project transformed the organization from a manual, reactive structure to a digitally enabled, proactive, and collaborative operation. The client now operates with greater speed, transparency, and consistency — attributes critical to competitiveness in the logistics industry.